How to Choose the Right Cutting Discs for Your Project

April 8th 2024

Are your cutting projects taking too long, costing too much, or leaving you with subpar results? The right cutting disc allows you to slice through the toughest materials with ease and precision. In this blog, we explore how to choose the right cutting disc for your needs.

Let's break down the top 10 factors to consider:

10 Factors to Consider When Choosing the Right Cutting Discs

1. Disc Type

The type of cutting disc you use lays the groundwork for your project's success. Each type excels in specific tasks and materials. Understanding these distinctions guarantees a safe and successful project with the best-cut quality.

These are three common metal-cutting disc types:

Abrasive Discs:

Aluminium oxide and silicon carbide are the materials that make these discs the workhorse of cutting. They expertly tackle steel, stainless steel, cast iron, and more. Although reliable, they generate heat that may cause minor warping or hardening.

Diamond Discs:

Diamond discs are studded with industrial diamonds set in a metal or resin base. These powerhouses effortlessly slice through hard, abrasive materials like ceramic, tile, and stone.

It is also possible to use them for thinner metals, such as aluminium and copper, as long as you are cautious. Diamonds produce a lot of heat.

Carbide-Tipped Discs:

Carbide-tipped discs combine super-strength carbide tips with a steel or aluminium base. It's the perfect tool for cutting thick or hardened steel.

While pricier than abrasive or diamond discs, they reward you with durability and precise cuts.

2. Material Compatibility

Great cuts require discs with the right grit and bond. It ensures smooth operation, less risk of accidents, and a flawless finish.

Here are some disc options tailored to specific metals:

Steel:

In most steel-cutting jobs, abrasive discs with tough aluminium oxide or silicon carbide grains are suitable. For heavy-duty work, carbide-tipped discs are your best bet.

Stainless Steel:

Discs with a harder bond and finer grit protect stainless steel's finish and prevent corrosion. In some cases, diamond discs are the right choice.

Aluminium:

Thinner discs with aluminium oxide or silicon carbide abrasives paired with a suitable bond are the way to go with aluminium. While diamond discs work, keep those speeds lower to avoid overheating the metal.

Cast Iron:

Consider strong, coarse-grit abrasive discs for handling cast iron. Choose carbide-tipped discs for heavy-duty cutting.

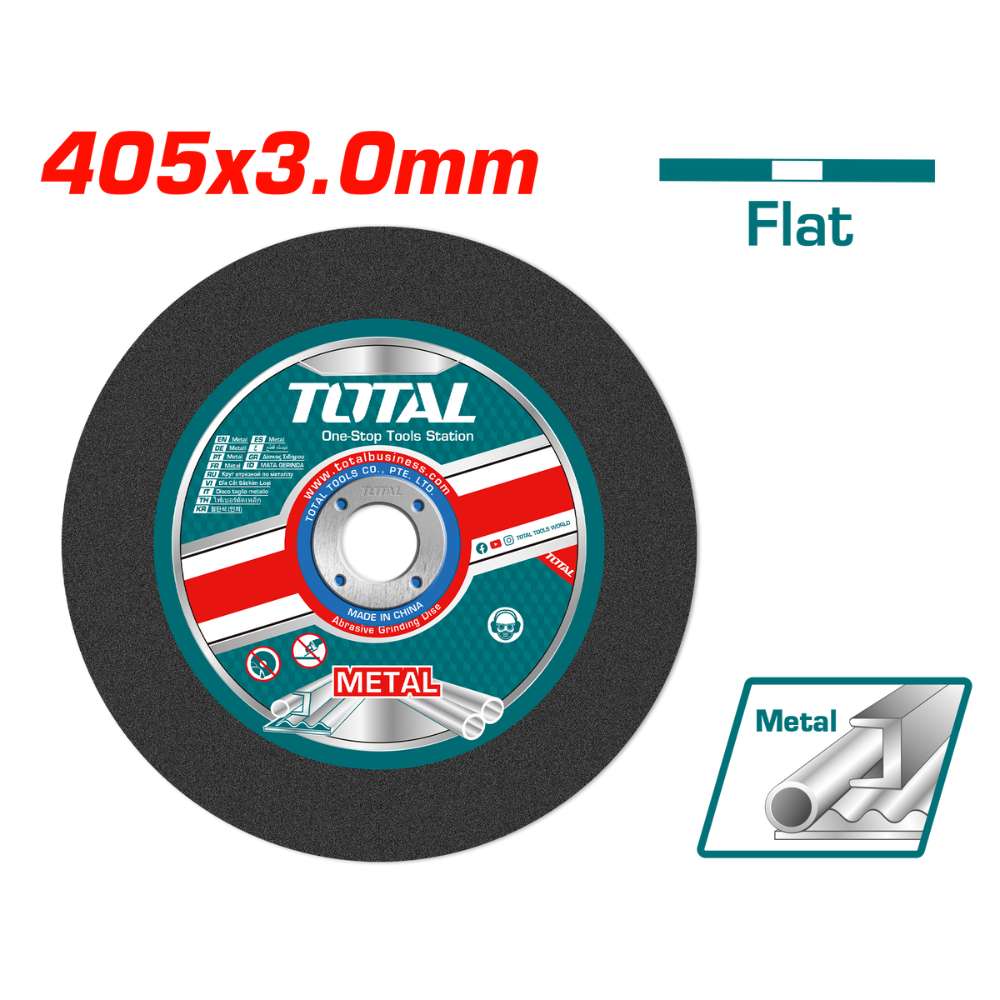

3. Disc Size

Size matters when cutting discs. The disc diameter is crucial to performance, safety, and efficiency.

Make sure your disc fits your tool and is suitable for the size and thickness of the material. It guarantees the cutting depth and keeps your equipment in top shape.

Metal cutting discs typically range from 4 to 14 inches in diameter. Make sure the disc size is right for your cutting tool.

For example, Angle Grinders handle discs from 4 to 12 inches. The cutoff saw is efficient for large projects and requires 12 to 14-inch circular saw blades.

4. Thickness

Cutting disc thickness is all about stability, wear resistance, and cutting speed.

Thicker discs are effective and last longer but might sacrifice speed, while thinner discs cut fast but wear out more quickly.

Thick Discs are known for power and durability. In jobs requiring tough materials or extended cutting, thicker discs provide more stability. They resist bending and handle the heat of a hard day's work.

Thin Discs are known for precision and speed. Thinner discs are better for fine cuts or when speed is critical. Their smaller profile dissipates heat quickly and leaves cleaner edges, ideal for careful craftsmanship.

Remember, thickness is a trade-off. Thinner discs may save you money, but they wear out faster. Thicker discs last longer, saving replacement costs over time.

5. Speed Rating

Every cutting disc has a maximum safe RPM (revolutions per minute) rating. It is not a suggestion – it's vital for your safety.

Using a disc at speed higher than its rating can lead to catastrophic failure – the disc could shatter, causing severe injuries.

Always check the maximum RPM of your cutting tool and the disc's speed rating. Never exceed the disc's rated speed. Matching tool and disc speeds ensure:

Every cutting tool has an RPM limit, and you should know yours. Inspect your disc and look for the speed rating printed on it. Never use a disc rated below your tool's RPMs.

Once you know the numbers, pick a disc rated the same as or slightly higher than your tool's limits. That gives you a safety buffer.

6. Quality and Brand

Regarding cutting discs, quality, and brand reputation are more than buzzwords. They impact safety, performance, and disc longevity.

Investing in trusted brands means you get the following:

- Rigorous Testing: A reputable brand puts its discs through multiple layers of testing, so you know they are reliable.

- Precision Manufacturing: Quality brands mean superior materials and construction, leading to clean cuts and longer disc life.

- Support and Warranties: It will be helpful to have someone by your side if anything goes awry and you need assistance.

7. Application

Cutting discs are specialised tools for a specific purpose. The type of work you're doing will determine the right disc size, material, thickness, and more.

Is it steel, aluminium, wood, or even plastic? Different discs are designed to handle specific materials. An unsuitable disc can shorten its life and cause poor cut quality.

You can choose particular discs for specific applications. For example, cutting discs for woodworking demands specific features like tooth design, kerf width, and those that prevent kickback.

If you are cutting plastic, you should choose discs designed specifically to prevent heat build-up and melt.

When cutting aluminium, use thinner discs with aluminium oxide or silicon carbide abrasives.

8. Safety Features

Cutting discs are powerful tools, and safety is non-negotiable. Here's what to look for:

Look for discs with extra reinforcement, especially for demanding tasks. These are more resistant to breakage under stress.

Some discs come with coatings that reduce heat buildup and sparks. Such safety features can prevent injuries and accidents.

9. Cost

Cost is always a factor, especially when dealing with project budgets. It's tempting to grab the cheapest cutting discs. But remember, you usually get what you pay for.

Higher-quality discs might have an upfront price tag, but they often last longer, cut better, and are safer. Long term, this can save you money.

The price of cheap discs may seem attractive. Still, you may have to buy replacements sooner, waste more material with sloppy cuts, or risk injuries.

Finding the right balance is crucial. Consider your project carefully and determine how much you should invest in your discs.

10. Safety Precautions

Cutting discs are powerful tools with the potential for serious harm. Never skip on safety. Here's your checklist:

- Gear Up: Safety glasses, gloves, and a face shield are essentials. Protect your eyes, hands, and face from sparks and debris.

- Follow the Rules: Your tool's manual has the do's and don'ts of safe cutting. Read it, live it, love it.

- Cut Smart: Keep a firm grip, apply steady pressure, and keep that disc square to the work.

- Clean Work Area: Ventilated, tidy spaces prevent surprises with sparks and flammable materials.

- Maintenance is Key: Check your tools and discs before every use. Replace dull, worn, or damaged items immediately.

How to Choose the Right Cutting Discs for Your Project: A Quick Guide

|

Factor |

Description |

|

Material |

Match the disc to the metal you're cutting (steel, aluminium, etc.) |

|

Disc Type |

Abrasive, Diamond, or Carbide-tipped for different applications |

|

Size |

Disc diameter should fit your tool and material thickness |

|

Thickness |

Thicker discs are stronger and thinner discs cut faster |

|

Speed Rating |

Match disc speed to your tool's RPM for safety and performance |

|

Quality & Brand |

Invest in reputable brands for reliability and safety |

|

Application |

Consider specific tasks (heavy-duty vs. precision) |

|

Safety Features |

Reinforcement and special coatings enhance safety |

|

Cost |

Balance value and quality based on your project needs |

|

Safety Precautions |

Always wear PPE and follow safe operating procedures |

FAQs

Q. How do I choose a cutting disc?

Select your cutting disc based on the material you're cutting, its thickness, desired speed and precision, and your focus on longevity versus upfront cost. Prioritise safety by matching the disc size and speed rating to your tool, and carefully consider quality brands for reliability.

Q. What thickness cutting disc should I use?

Thicker discs provide strength and durability for tough materials and extended use. In comparison, thinner discs offer faster cutting, less heat buildup, and clean edges, for precision tasks. Choose the thickness that best balances your need for toughness and precision.

Q. Can I use a 125mm disc on a 115mm grinder?

No. It is a safety hazard. Never use a disc larger than the maximum size specified for your grinder, as this can lead to disc failure and serious injuries.

Q. Which disc type is suitable for cutting material?

Carefully study the disc's labelling and specifications. It will indicate the type of material it's designed for (steel, stainless steel, aluminium, etc.) and its abrasive type, which should be compatible with the specific metal you're working with.

Conclusion

It can seem complicated at first, but following these guidelines, you can choose the right disc for the job.

Even the best disc is only as good as the person using it. Work safely, stay aware, and when in doubt – ask for help before starting to cut. Always buy the highest quality cutting discs from FEPY at the most cost-effective prices.

FEPY is a rapidly growing e-commerce platform for construction materials and tools in the UAE. Enable notification settings to avoid missing limited-time deals on FEPY.